For most people, the first thing that comes to mind when they think of Leonardo da Vinci is the Mona Lisa, or his sketches of the Vitruvian man. Fans of pulp fiction or popular cinema might even find their minds drifting to memories of The Da Vinci Code, the mystery thriller. Not me, though. I’m engaged in the study of friction, the force resisting the relative motion between surfaces. What most people may not realise is that Leonardo was responsible for the first systematic study of friction.

Friction is important to our daily existence and is present all around us. Starting with brushing teeth in the morning, driving a car and relying on a good grip of tyres, or looking at a mechanical watch with a confidence that all miniature parts are functioning properly to show us a correct time. As a field of science, study of friction is part of tribology, once called “the most important subject no one has heard of”.

Tribology is the science and engineering of interacting surfaces in relative motion. It includes the study and application of the principles of friction, lubrication and wear. The word tribology derives from the Greek “tribo” (“I rub”) and the suffix “logos” (“study of”, “knowledge of”). The word is just over 50 years old and was coined by Peter Jost, a British mechanical engineer considered the founder of the discipline. A report commissioned by the UK government, highlighted the cost of friction, wear and corrosion to the country’s economy.

In 1966 that cost was estimated at 1.1%-1.4% of national GDP and, as a result, the UK government established several national centres to address problems associated with friction.

Early works

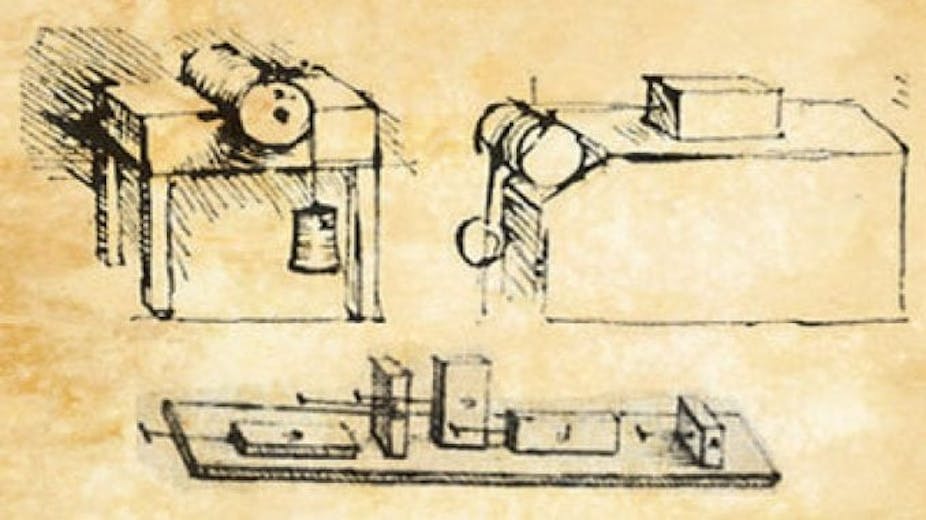

Leonardo understood very well that friction is a limiting factor in the design of his revolutionary machines. He worked on the subject for more than 20 years, as evidenced by his beautifully illustrated notes and sketches. Leonardo distinguished between rolling and sliding friction and made observations that surface roughness has an impact on how easy it is to move different materials. His tribological experiments were dictated by his curiosity, but perhaps mainly by his pragmatic nature, as he needed reliable mechanical solutions for the design of his components. In his notebooks, we can find evidence of studying friction of simple blocks, but also screw threads, wheels and axes.

He was the first to record the laws of friction and he managed to achieve that by designing experiments using strings, pulleys and weights. Experiments based on the same principles are carried out on modern friction testers called tribometers. Some of those testers offer an ability to measure frictional forces at a tiny scale and might cost well above £200k due to their complexity and sophisticated nature of measurement electronics.

As it turns out, Leonardo never published his findings on friction – and he never got credit for his visionary findings. It was not until 1979, when the seminal book on the history of tribology was published, and Leonardo’s now famous tribological sketches were revealed.

Modern applications

Today, tribologists around the world are building on foundations laid by Leonardo. Modern studies confirm the importance of urgent development of low friction surfaces to control the energy consumption, economic expenditure and CO₂ emissions on a global scale. Understanding the fundamentals of friction is key for a design of reliable and efficient electrical vehicles, wind turbines, and medical implants such as hip replacements.

I have spent my career designing, testing and characterising surfaces by applying functional coatings, a field called “surface engineering”. My work involves using various tribometers and I find it extremely useful to reflect on my experiments and relate them back to early Leonardo’s studies.

Five centuries after Leonardo’s death and 50 years after tribology word was coined, tribologists are looking at a wider context of digital technologies and are designing functional surfaces that are sensing, responding and connected.