We manufacture over 300m tonnes of plastics each year for use in everything from packaging to clothing. Their resilience is great when you want a product to last. But once discarded, plastics linger in the environment, littering streets, fields and oceans alike. Every corner of our planet has been blighted by our addiction to plastic. But now we may have some help to clean up the mess in the form of bacteria that have been found slowly munching away on discarded bottles in the sludge of a recycling centre.

Plastics are polymers, long thin molecules made of repeating (monomer) building blocks. These are cross-linked to one another to build a durable, malleable mesh. Most plastics are made from carbon-based monomers, so in theory they are a good source of food for microorganisms.

But unlike natural polymers (such as cellulose in plants) plastics aren’t generally biodegradable. Bacteria and fungi co-evolved with natural materials, all the while coming up with new biochemical methods to harness the resources from dead matter. But plastics have only been around for about 70 years. So microorganisms simply haven’t had much time to evolve the necessary biochemical tool kit to latch onto the plastic fibres, break them up into the constituent parts and then utilise the resulting chemicals as a source of energy and carbon that they need to grow.

Enzyme innovation

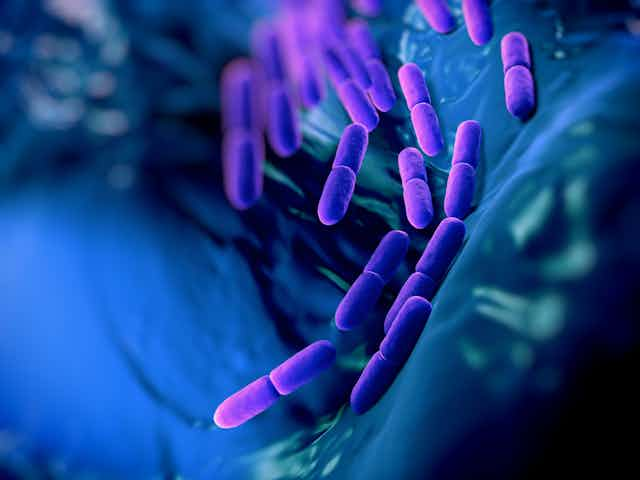

Now a team at Kyoto University have, by rummaging around in piles of waste, found a plastic munching microbe. After five years of searching through 250 samples, they isolated a bacteria that could live on poly(ethylene terephthalate) (PET), a common plastic used in bottles and clothing. They named the new species of bacteria Ideonella sakaiensis.

You may think this is the rerun of an old story, as plastic-eating microbes have already been touted as saviours of the planet. But there are several important differences here. First, previous reports were of tricky-to-cultivate fungi, where in this case the microbe is easily grown. The researchers more or less left the PET in a warm jar with the bacterial culture and some other nutrients, and a few weeks later all the plastic was gone.

Second - and the real innovation - is that the team have identified the enzymes that Ideonella sakaiensis uses to breakdown the PET. All living things contain enzymes that they use to speed up necessary chemical reactions. Some enzymes help digest our food, dismantling it into useful building blocks. Without the necessary enzymes the body can’t access certain sources of food.

For example, people who are lactose intolerant don’t have the enzyme that breaks down the lactose sugar found in dairy produce. And no human can digest cellulose, while some microbes can. Ideonella sakaiensis seems to have evolved an efficient enzyme that the bacteria produces when it is in an environment that is rich in PET.

The Kyoto researchers identified the gene in the bacteria’s DNA that is responsible for the PET-digesting enzyme. They then were able to manufacture more of the enzyme and then demonstrate that PET could be broken down with the enzyme alone.

First real recycling

This opens a whole new approach to plastic recycling and decontamination. At present, most plastic bottles are not truly recycled. Instead they are melted and reformed into other hard plastic products. Packaging companies typically prefer freshly made “virgin” plastics that are created from chemical starting materials that are usually derived from oil.

The PET-digesting enzymes offer a way to truly recycle plastic. They could be added to vats of waste, breaking all the bottles or other plastic items down into into easy-to-handle chemicals. These could then be used to make fresh plastics, producing a true recycling system.

Manufactured enzymes are already used to great effect in a wide range of everyday items. Biological washing powders contain enzymes that digest fatty stains. The enzymes known as rennet that are used to harden cheese once came from calfs’ intestines but are now manufactured using genetically engineered bacteria. Maybe we can now use a similar manufacturing method to clean up our mess.