Coal powered much of the industrial revolution and continues to fuel economic growth in developing nations, including China and India.

The dark side of coal, however, is that it generates large quantities of the heat-trapping greenhouse gases, mostly carbon dioxide (CO2), that lead to climate change. This CO2 pollution is in addition to other emissions from coal burning that lead to thousands of premature deaths per day around the world.

It was once thought that the CO2 emissions from coal power stations could be controlled by burying CO2 underground economically. However, our recent analysis published in the journal Environmental Science & Technology shows that the concept of carbon capture and sequestration (CCS) will be significantly more expensive than previously thought because previous studies miscalculated the energy required. As such, it’s unlikely to provide an economically viable solution to CO2 pollution from coal-based power generators.

Coal and global carbon budget

As countries think about possible ways to cut their greenhouse gas emissions at the UN Climate Summit in Paris, developing a strategy to curb emissions from coal will be essential to taking meaningful action on climate change.

Globally, the use of coal for heat and electricity accounted for over 14 billion metric tonnes (gigatons) of CO2 emissions in 2014 according to the International Energy Agency. This comprises about one-third of the world’s total greenhouse gas emissions.

Atmospheric concentration of CO2 today is about 400 parts per million (ppm). Our analysis shows that if today’s coal power plants continue operating through the end of their expected service life, they would collectively emit 260 gigatons to 350 gigatons of CO2 by 2050, which would increase CO2 concentration by another 13-18 ppm.

Scientists have recommended that CO2 concentration needs to stay within 430-480 ppm to avoid dangerous interference with the climate (defined as two degrees Celsius rise in temperature relative to preindustrial revolution). Coal use in existing power plants alone will thus consume about a third to a half of the remaining “carbon budget” that humanity has to avoid reaching that threshold.

CCS to the rescue?

Acknowledging the importance of coal in world economic growth alongside the need to reduce CO2 emissions has led to great interest in “Carbon Capture & Sequestration” (CCS) technology.

Prominent studies such as Pacala and Socolow, Williams et al, and Hertwich et al suggest a suite of strategies to meet the CO2 challenge. Notably, all these studies assume the widespread deployment of CCS. For example, Hertwich et al project that CCS would contribute to nearly 85% of global CO2 emission reduction by 2050.

CCS essentially involves keeping CO2 out of the atmosphere by capturing the CO2 produced from fossil fuels, compressing it under high pressure, and then transporting it via pipelines or ships for storage in the deep ocean or underground geological reservoirs.

There are no large-scale CCS power plants (defined as more than 500 megawatts of power) currently in operation, and most of our understanding of the technology comes from pilot-scale plants in the 1990s and subsequent scientific models of the capture process.

Capturing the CO2 from the exhaust of coal power plants requires energy in the form of steam and electricity. Because some energy is used for CO2 capture, CCS reduces a power plant’s electric power output and/or increases its fuel input. This creates an “energy penalty” for power plants that increases their operating costs. In addition, there is the large capital costs of building the CCS system.

Previous studies typically estimated that the fuel cost of coal power plants capturing 90% of their CO2 emissions would increase by about 30%-60%. However, data emerging from recent pilot or small-scale commercial CCS plants have consistently indicated that in reality the energy penalty and fuel costs are much higher. So why the discrepancy?

The numbers don’t add up

To understand why the estimates from earlier pilot studies and models don’t align with more recent observations about the energy penalty and costs of CCS, we decided to revisit some of the assumptions and calculations in the CCS energy analysis and economics literature.

Our research, which was funded by the US National Science Foundation, showed that the fuel costs of coal-fired power plants can increase by up to 136% with the addition of a CO2 capture plant. That is, the fuel costs, which dictate the marginal cost of electricity generation (and consequently profits) for a power plant, would more than double in a CCS future.

In our analysis, we quantified the CCS “feedback loop,” which created a more accurate estimate of the energy penalty. The feedback loop arises because the excess fuel burnt to generate additional electricity and steam for CCS itself creates CO2 that must be captured and stored. Capturing this CO2 in turn requires more fuel, which again creates more CO2. Although previous studies had defined an energy penalty, they ignored this obvious feedback loop, with the result being a gross underestimation of CCS costs.

We traced the confusion to how a 1990s pilot study was interpreted within the CCS energy and economic literature. That pilot study reported that the power output of their 513 megawatt power plant dropped to 336 megawatts because of the carbon capture equipment added on. That corresponds to a 35% energy penalty, meaning it takes 35% more energy to produce to the same megawatt of power when carbon is removed from the fuel.

Discrepancies with the actual energy penalty arose when subsequent studies used this 35% energy penalty number without fully incorporating its underlying assumptions – that is, as plants capture more carbon, they need to burn more fuel to capture more carbon.

This added energy translates directly into costs. When the constant fuel input is considered, the required steam for carbon capture can be about 40%-60% of the total steam produced in the power plant’s boiler. Since this steam cannot be used to generate power, it means lost revenue and a profit penalty for the power plant operator.

Renewables look better

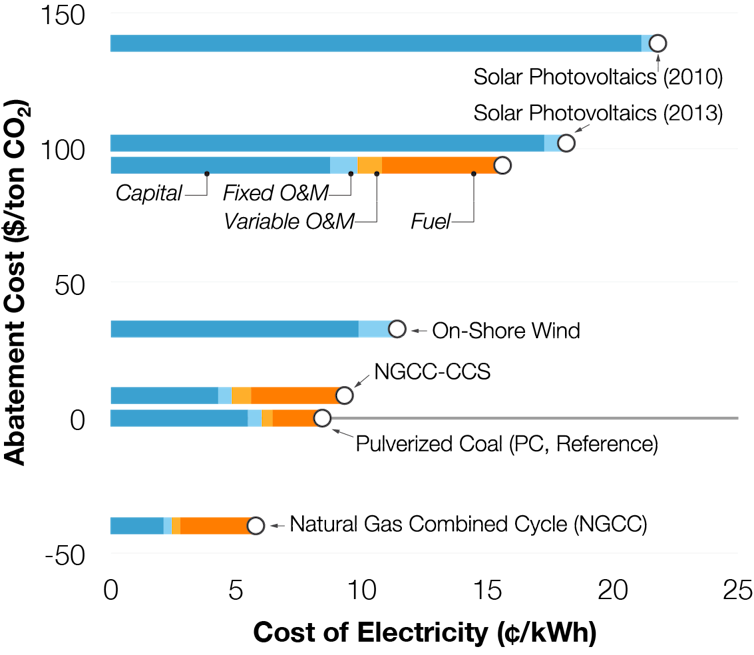

Our analysis shows that CCS is more expensive compared to other forms of low-carbon power generation than previously thought.

Once the energy penalty of the feedback loop is figured in, we found renewables such as wind and solar photovoltaics are already more cost-competitive than coal with CCS. And projections show wind and solar will continue to become cheaper.

Natural gas, which generates about half the amount of CO2 than coal for every unit of power it produces, could also provide a cheaper alternative to coal both with and without CCS.

Keeping the coal in the ground is not only the most economical way of reducing carbon emissions, it is a sure way to save thousands of lives every day due to cleaner air. It is a classic case of “prevention,” through decarbonization of energy systems, being better and cheaper than the “cure” of CO2 capture.