Should Australian truckies feel a little nervous about the rise of platooning?

Truck platooning has burst into both the international and Australian scene - with recent announcements including Elon Musk’s new Semi, and approval for Peloton Technology to conduct Australian trials.

Read more: How to make a driverless car 'see' the road ahead

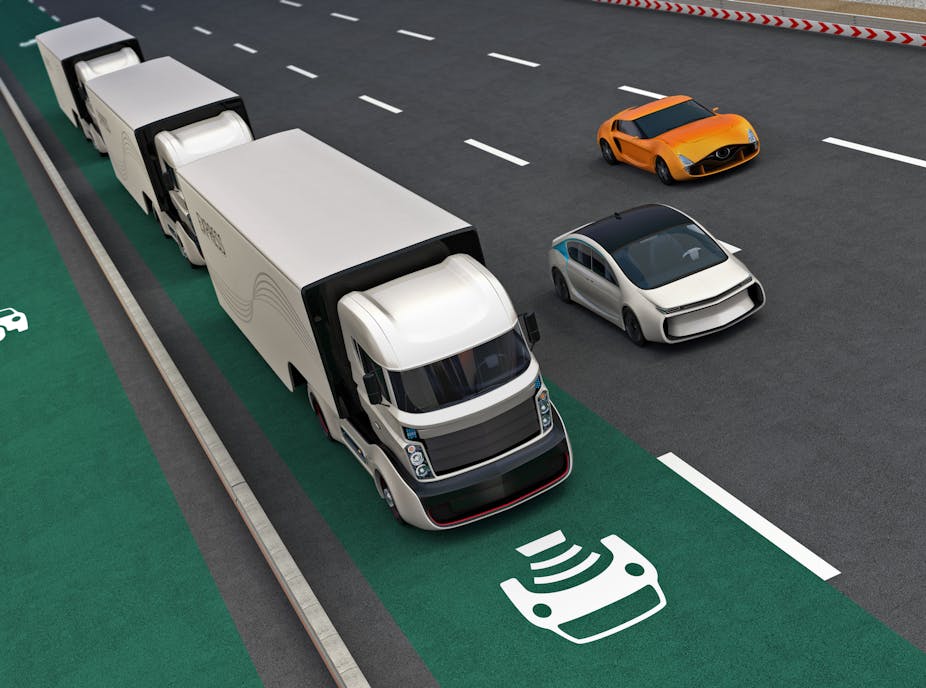

Platooning involves a number of trucks closely following one another, connected using vehicle-to-vehicle communication. Typically the lead truck does most of the driving “work”. Models vary in terms of what the drivers in the following trucks do, from having attentive drivers to having no driver at all.

So why don’t we have widespread platooning already? Well, there are some challenges that are yet to be fully solved.

Trucks operating manually (in the blue) and the new close-following platoon model (in the red). Source 123rf.com/tele52/aurielaki/Michael Milford.

Trucks operating manually (in the blue) and the new close-following platoon model (in the red). Source 123rf.com/tele52/aurielaki/Michael Milford.

The benefits of platooning

On an average day, nearly five million tonnes of freight is moved within Australia, of which 70% is carried by trucks. Road freight has doubled in the last 20 years in Australia. Platooning could add some benefits to this situation.

For example, trucks can follow each other closely, leading to better fuel efficiency, perhaps up to 15%.

Safety is also better in some circumstances. For example, when the lead truck brakes for an obstacle, the trailing trucks can brake simultaneously, instead of waiting for a human driver to visually realise the truck in front is slowing.

In the case of the trailing trucks being automated without a driver, there are also labour savings.

While there are some differences between the US market and the Australian market, the overall challenges and opportunities are similar - financial and safety benefits in the US will also likely be relevant in Australia.

Continuous communication

Vehicles are typically connected through a Wi-Fi connection on a reserved radio spectrum at 5.9 GHz.

The reliability and security of vehicle to vehicle communication is key in platooning. If the communication link is being (at least partially) relied upon for safety-critical matters like braking, it must be reliable. Fail-safes must also kick in if the communication link is dropped.

Security from malicious parties is also an issue - one can imagine a scenario where people might try to steal the last truck by electronically “disconnecting” or taking it over.

There’s also the issue of sufficient spectrum allocation for vehicle-to-vehicle communication, a topic of active research focus.

New versus existing infrastructure

Like self-driving cars, there are varied models for how platooning will work. Some require no changes to the road infrastructure whatsoever, relying entirely on vehicle smarts and sophisticated communication between vehicles.

Others rely on augmenting the road infrastructure with extra sensors, or even building dedicated roads and “inland ports”. Under this model, governments or road operators must make further investments, which brings up the issue of how this investment is recouped.

But augmented or dedicated infrastructure would significantly reduce the complexity and danger of platoon operations, meaning the higher efficiency might pay for itself.

Dedicating separate infrastructure to platooning trucks would simplify the technological challenge, at a cost. Source 123rf.com/tele52/aurielaki/Michael Milford.

Dedicating separate infrastructure to platooning trucks would simplify the technological challenge, at a cost. Source 123rf.com/tele52/aurielaki/Michael Milford.

The vigilance issue

Any system that introduces partial, but not fully autonomous operation can suffer from a vigilance problem. This could arise in a situation where there are drivers in the trailing trucks in a platoon, but they’re relying to some extent on the vehicle in front plus vehicle-to-vehicle communications to manage some of the driving.

As we see in the case of the recent Tesla fatality, humans can be poor at being an always vigilant “backup” to a mostly automated system. This is especially true when the human is required to act very quickly when something goes wrong, as is the case with self-driving cars.

Read more: The future of flying cars: science fact or science fiction?

The consequences of not being able to intervene sufficiently quickly are magnified when multiple 30 or 40 tonne vehicles moving at or above 80kmph are involved.

Less incidents, but they might be bigger

If done well, platooning will be much safer, resulting in fewer accidents due to human error.

But, like a freight train crash, if and when things go wrong, the outcome will be magnified by the close proximity of many heavy, high speed vehicles.

Currently some USA states decree a 150 metre minimum follow distance for trucks.

Even with perfect reaction speed, a truck only a few metres behind the lead truck will have a smaller set of options for reacting when something goes wrong in front of it.

The future of platooning

Platooning development is occurring in parallel with the race to develop autonomous consumer vehicles, also known as self-driving cars. But the motivations for platooning are different, and new technological challenges are involved.

Technologically, it is an easier overall challenge than making a genuinely Level 4 or Level 5 self-driving car. But there is a downside: the greater consequences if something goes catastrophically wrong.

As trials ramp up overseas and commence in Australia, we will soon be in a much better position to evaluate whether platooning is a viable future for Australian trucking.