Talking only about 3D printers and guns is like watching a movie in fast forward, slowing down only to watch the bits where people die.

But in the whole story of 3D printing, guns are only one short scene - the rest of the story is far more uplifting. A whole research industry has flourished with advancements in medicine, manufacturing and architecture - breakthroughs which have actually been developed for decades.

You might be surprised to find out 3D printers have been around since the mid-1980s, but the devices themselves and the material they consumed were so expensive (with small, simple structures costing hundreds of dollars) that the idea of a consumer-level 3D printer was ludicrous. Over the past couple of decades, though, the cost of these consumer level printers has plummeted from more than US$110,000 to as low as US$350.

This resulted in a burgeoning interest from the “hacker” community: not a shadowy bunch of cybercriminals, but groups of very clever and motivated people who like to pull things apart and put them back together better, such as Melbourne’s Connected Community HackerSpace. HackerSpace runs community-operated workshops, where people can meet and work on technology projects like 3D printing.

Research into 3D printing is also blooming in more formal academic centres, with recent breakthroughs including 3D printed medicines and microscopic batteries.

The message is simple: 3D printing will save far more lives than it will ever take - and here’s why.

Saving lives

One of the very few non-gun-related 3D printing stories to make the mass media this year was about Australian researchers who developed a technique which may lead to the production of human tissues, and even organs.

A 3D printer can create a scaffold from implantable biomaterials that degrade safely in the body, allowing new tissues to grow.

New developments also allow printing of living cells or tiny pieces of tissue harvested from a patient biopsy and grown in the laboratory to engineer new functional tissues. Because in the ideal situation this tissue originates from the patient’s own cells, the chance of rejection is almost nil. And the technique is not limited to a specific tissue – it is a generic approach.

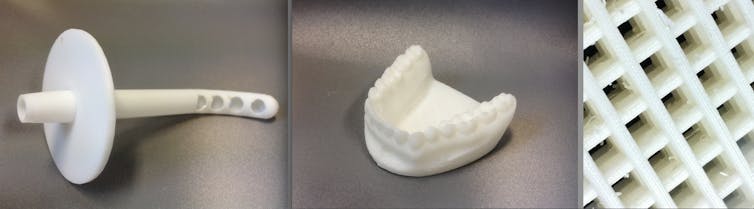

Custom medical implants are produced by 3D printing techniques to replace damaged or missing tissues, such as sections of the skull after road trauma. We could take this a step further: imagine if you could print and store your whole skeleton so you have spare parts ready to go, if necessary!

Surgical 3D printed models produced from CT scan data can also help surgeons to plan and navigate difficult procedures.

While significant research challenges must still be overcome to generate viable human-sized 3D organs, this could eventually eliminate organ donor waiting lists. Simply replacing a diseased organ might one day solve diseases we are struggling to control.

Medical applications for 3D printing seem almost endless.

Moving to manufacturing

There are as many stories about how we can improve not only the life of an individual, but the lives of everyone on the planet. From freeing artistic expression to creating better house designs, 3D printing allows a new level of creativity to influence design.

3D printing food may even help alleviate the growing global demand for meat and consequent environmental impacts. NASA has already started looking into a food printer for the International Space Station.

In this brave new world, the traditional manufacturing limits are lifted. Shared designs online will enable rapid refinements and bring the iterative design process into the hands of the layperson.

And perhaps the most exciting prospect is putting this potential in the hands of children, whose minds are not yet so constrained by traditional methods.

Back to the guns

Recent media attention on 3D printing has focused on the printing of guns. But 3D printers can print pretty much any shape you can imagine - guns just happen to be one of those shapes.

They can also produce objects in a wide range of materials, including metals. See titanium and aluminium-printed objects in the video below.

The simple truth is six months ago, you couldn’t print your own working gun. Today, you can, and in another six months, there will have been more than a year of innovation in the printing of guns and each iteration will solve some small problem.

This will mean that at some point in the near future, a 3D printed gun is likely to be every bit as capable as a “real” gun. It is almost inevitable that we will read about the first homicide with a 3D printed gun, and unfortunately, it will probably be sooner rather than later.

What is clear from recent events is that 3D printing, like many technologies before it, will need effective laws and regulation. And while it sounds obvious, regulation will need to balance people’s freedom to use the technology, with prosecuting those who abuse it and also to protect others from the consequences of that abuse.

While the wonderful thing about 3D printers is they enable innovation in so many aspects of our lives, the flip side of the coin is this could also involve hurting other people. To strike this balance will be difficult, complex and a continual work in progress. But the reality is in 3D printing’s history, a 3D printed gun has killed no one, but numerous lives have already been saved.