A new coating for cotton that is 1½ times more water-repellent than Teflon can survive for dozens of machine washes, say the Australian scientists who developed it.

A team from the Australian Future Fibres Research and Innovation Centre at Deakin University says the ultra-repellent “superhydrophobic” coating is chemically bonded with UV irradiation in a way that makes it more durable and water resistant than previously possible.

The superhydrophobic technology involves dipping the fabric in wet chemicals containing nanoparticles and polymers to create one thin layer of coating at a time - a simple process that allows for precise control over the coating thickness, but which is weak and prone to breaking down quickly.

The Deakin scientists strengthened the bonds between layers and improved the durability of the coating by adding a group of chemicals that stick together more tightly when exposed to UV light. “We also used a floroalkyl chemical on the top layer to reduce the surface energy. That’s why the coating is durable, but still provides good water resistance,” said Associate Professor Tong Lin, who lead the research.

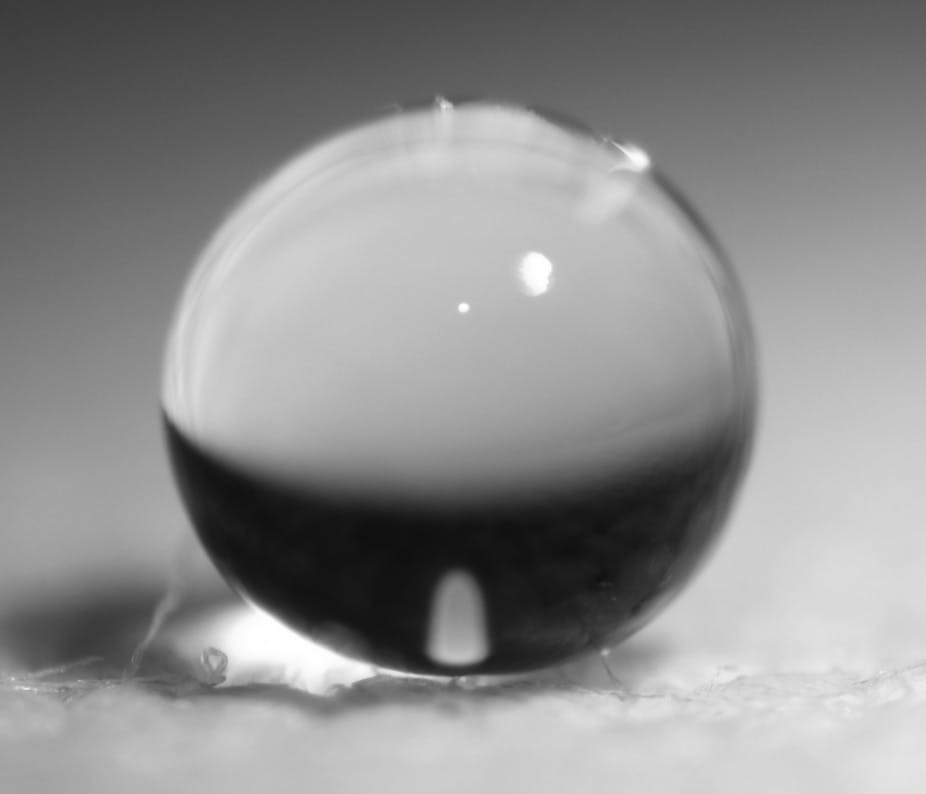

When applied to cotton, the new coating repelled water and other materials at a far greater rate than other superhydrophobic surfaces. The contact angle - which is the angle of the leading edge of a water droplet on the surface when measured from the centre of the droplet - was 154 degrees, much greater than car wax (90 degrees), Teflon (95 degrees), and products used on car windscreens (110 degrees). The coating on the fabric was also still intact after 50 machine washes.

“Superhydrophobic surfaces have a wide range of applications including repelling water, self-cleaning, anti-contamination and corrosion protection,” said Professor Lin.

“What we’ve developed is coating that is more water-repellent than Teflon and highly durable against acids, organic solvents such as cooking oil and repeated machine washing.”

As well as using the technique on cotton fabric, the team is looking into potential medical applications.

“We’ve used a similar method for antibacterial coating of the scaffolds, or artificial structures, used to support the growth of new tissue, such as skin, outside of the body,” Professor Lin said.

“Our tests have shown that the coating is stable, has strong antibacterial performance and does not interfere with cell growth. It’s a promising advancement in repairing and regenerating the likes of skin, bone, nerves and muscles.”