Semiconductors are the basic building blocks of microchips. These technological marvels are in everything from lightbulbs and toothbrushes to cars, trains and planes, not to mention the vast array of electronics that have become integral to many people’s daily lives.

The 21st century chip manufacturing industry has been described as “at least as significant geopolitically as oil was in the 20th.” But semiconductor manufacturing requires vast quantities of water to keep machinery cool and wafer sheets free of debris, and the unfolding climate emergency puts the industry at risk.

Despite the industry’s dependence on water, little attention has been paid to how changing environmental conditions may impact it. Reporting by journalists and think tanks tend to overlook climate as a risk factor for the future of the industry.

Yet, globally and regionally there are signs of trouble. Taiwan, for example, produces about 90 per cent of the world’s most advanced semiconductors and has been experiencing a significant drought since 2021.

The drought is bad enough that Taiwanese farmers are being paid to keep their fields fallow so water that would otherwise go to agriculture can be fed into semiconductor manufacturing plants. Taiwanese manufacturing plants have even had to resort to trucking water from one watershed to another to overcome shortages.

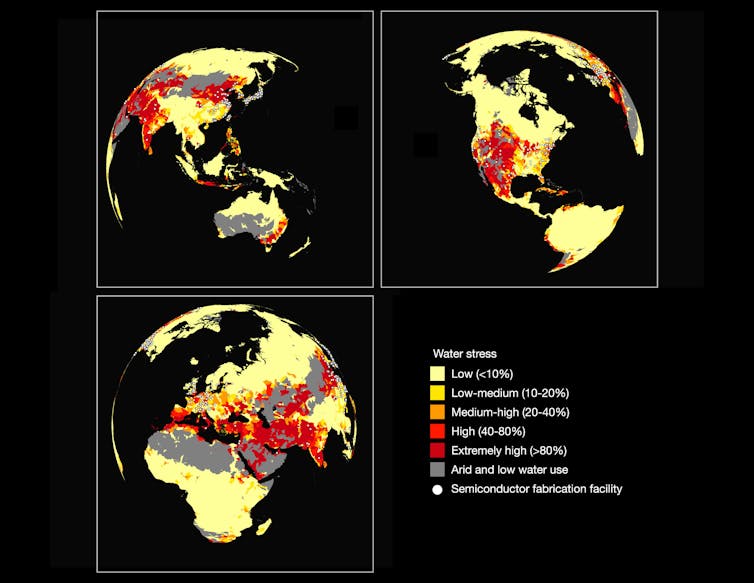

Publicly available data on climate change-induced water stress, combined with data on the location of existing, planned and announced semiconductor manufacturing facilities around the world, all point to global patterns of concern for the future of semiconductor manufacturing.

Looming water shortages ahead

No matter the climate change scenario considered — whether optimistic, business-as-usual or pessimistic — a minimum of 40 per cent of all existing semiconductor manufacturing plants are located in watersheds that are anticipated to experience high or extremely high water stress risk by 2030.

High-risk watersheds are those in which 40 to 80 per cent of the total renewable surface and ground water available for all purposes (e.g., irrigation, industrial, domestic use) are in use. Extremely high-risk watersheds are those in which greater than 80 per cent of the total renewable surface and ground water are in use.

Much of the recent concern expressed over semiconductor manufacturing paints the issue in geopolitical terms about interstate rivalry, especially between China and the United States.

Both the U.S. and Europe have announced major government funding for the semiconductor manufacturing industry, especially to bring back the facilities of companies that spent decades setting up manufacturing capacity outside of those regions. However, the manufacturing facilities being announced or under construction in the U.S. and Europe are all located in regions that are already facing significant water stress.

Intel, Taiwan Semiconductor Manufacturing Company (TSMC) and Samsung are all building new facilities in the southwestern U.S. — a region that has been under official drought conditions since 1994. In 2021, the U.S. Bureau of reclamation made its first ever shortage declaration for the Colorado River basin.

Future climate change scenarios suggest more than 40 per cent of all new semiconductor manufacturing facilities announced since 2021 will be in watersheds likely to experience high- or extremely high-risk water stress scenarios.

Put simply, climate change and water shortages is creating risks for semiconductor manufacture in both the short- and long-term.

The state of the industry

Semiconductor manufacturing facilities are multi-billion dollar investments. One does not simply pick a facility up from one location and plunk it down elsewhere if local water conditions become problematic.

As worrying as the future might be for the sector, aggregate water stress risks only tell part of the story. The importance of particular nodes in global production networks for semiconductors is another key factor.

For example, TSMC is widely acknowledged as a world leader in manufacturing advanced semiconductors for companies like Apple, Nvidia and Cerebras. Yet, the facilities where TSMC manufactures for those companies are located in just three sites in Taiwan. This makes the global production networks that manufacture these technologies quite fragile. Semiconductors, especially the most advanced ones, rely on a network of only a handful of facilities like TSMC’s.

Customers of those facilities cannot easily switch to another supplier in the face of a disruption, so issues that arise at a single facility can cascade through global supply chains. This can impact a wide variety of commodities that make use of semiconductors, as was experienced during the COVID-19 pandemic.

Major semiconductor manufacturers like Intel and TSMC claim to take water stewardship seriously. Yet, their own company reports suggest there may be trouble ahead. Despite TSMC’s investments in water reclamation and recycling, the company anticipates being able to provide only two-thirds of the daily water consumption needed at its Taiwan-based facilities.

Intel, meanwhile, claims to achieve net positive water use across its manufacturing network as a whole. But, it manages this achievement only by counting surplus water at locations in one part of the world against water deficits at its facilities elsewhere.

A concerning future ahead

It is not going to be easy — or cheap — to overcome the chronic water stress risks for the semiconductor industry arising from the unfolding climate emergency. Conflicts already exist between the sector and other water users.

Even as individual companies make impressive water use efficiency improvements, these efforts do not automatically result in systemic efficiencies across semiconductor production networks. And no amount of efficiency will ever overcome the problem of the water that is needed for semiconductor manufacturing also being needed by other users.

It may still be possible to avoid some of the worst consequences of locking in future water stress for the sector by rethinking the location of future facilities that have been announced, but are not yet under construction.

Without secure access to large volumes of water there are no semiconductors, and without semiconductors there are no electronics. The climate emergency is a major driver of water stress both now and in the future. Can the tech sector cope? It remains to be seen.