Australian industries have reached a turning point. With old industries on the way out, the Australian manufacturing sector’s biggest challenge is to move from a low-cost mass production model to one that exploits niche markets and adds value to the global supply chain.

Research-driven technological advances are an essential part of that process. By building upon the country’s natural advantages, such as mineral and energy resources, this kind of progress can foster exciting, sustainable industries. The perfect example is graphene.

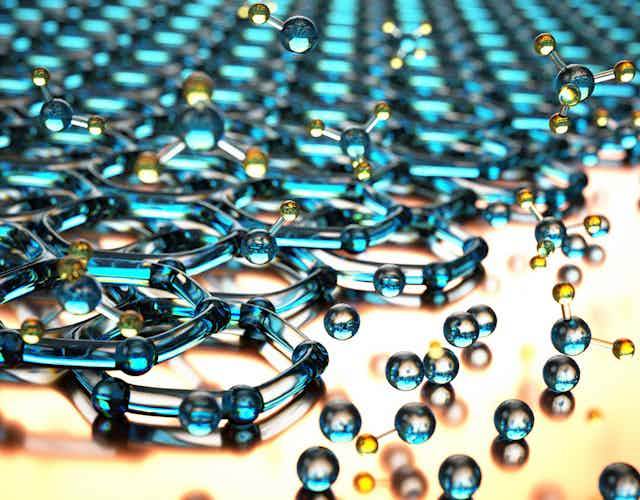

Graphene, you’ll have heard, is a remarkable material: it is extremely light and strong, can confer that strength to other materials and has better electrical conductivity than copper; all qualities found in single sheets a million times thinner than a human hair. It should be no surprise, then, that this material has the potential to turn many high-tech industries on their head.

What exactly does the substance offer? To name, but a few:

- more powerful, faster-charging batteries

- dramatically improved data storage

- far more efficient solar cells

- lighter and stronger automobiles, boats and planes.

The potential of this “super material” is so great that the European Union intends to spend US$1.35 billion over the next ten years to take graphene from the laboratory to commercial products.

The biggest current obstacle to its widespread use is generating sufficient quantities of high quality graphene at low cost for industrial applications.

Peeling away individual graphene sheets from graphite (the “pad” to graphene’s “paper”) would appear to be easy — the two English physicists who won the 2010 Nobel prize for isolating graphene did this by using Scotch tape, repeatedly splitting graphite flakes until they obtained a single graphene layer — but this type of mechanical exfoliation is not scalable, and prohibitively expensive.

An alternative approach to mechanically separating the graphene layers in graphite is to chemically change the properties of the graphene layers in the graphite so that they no longer want to stick together and can be dispersed in water (or some other solvent).

The resulting graphene oxide layers can then be converted back into single graphene sheets.

Graphene water and solvent dispersions can either be coated on surfaces through a range of means or used in mixtures such as plastics to form composites, both industrially scalable processes.

What does this have to do with Australian manufacturers?

In 2012, the bulk of the global graphite supply came from China, India and Brazil, with China producing 70% (although its reserves are becoming depleted).

In Australia, graphite has been mined on the Eyre Peninsula in South Australia at irregular intervals since 1910, but in the past 18 months there has been a spate of new graphite discoveries of high quality ore.

Strategic Graphite Limited will reopen the historic Uley mine in the Lower Eyre Peninsula region in 2014 and become the only operating graphite mine in Australia.

While this mine will employ up to 50 people in the state most affected by the impending loss of major employers, like most other mining products in Australia, the graphite will be sent offshore to be substantially value-added by incorporation into lubricants, batteries, brake linings and so on, forfeiting not just financial gain, but further employment and new industries.

So, Australia has an excellent high-quality raw material (graphite) supply and the technology and expertise to turn that raw material into a high-tech material.

What is now needed is an alignment of skills and resources that can turn these opportunities into a viable Australian manufacturing operation.

The gains to be had are enormous. Conversion of South Australian graphite to graphene has the potential to increase the value of the commodity from US$2,000/tonne for graphite to at least US$1,000,000/tonne for graphene, at a cost similar to or lower than many of the precious metals that could be replaced by graphene in electronic devices.

Imagine the additional value in putting a few milligrams of graphene into the capacitors or batteries of the 1.1 billion mobile phones produced worldwide each year. At each of those stages, employment increases.

Last month, the ARC Centre of Excellence for Electromaterials Science was re-funded for seven years. Some of that funding will be used for the development of new fabrication protocols and new uses of graphene in energy and medical bionics as well as diagnostics and soft robotics.

As much as this will increase the commercial potential of the material, what is really needed is a financial and business framework allowing researchers and developers to work with those skilled in the art of business development.

At present, the mechanisms in the Australian funding sector providing support for commercial research aid existing businesses, but not the creation of new enterprises.

Finding ways to fund such ventures is critical in a country that is blessed with tremendous resources like graphite as well as extraordinary young researchers. But the empowerment of those young researchers to develop the business and entrepreneurial skills to create our manufacturing future is also essential.

The last Federal Government committed more than A$3 billion to maintaining an ailing manufacturing sector over a ten-year period. The European Union, on the other hand, has committed a third of that to creating exciting new products and associated manufacturing industries based on just one material. Which approach makes sense to you?