The world faces an increasing shortage of housing and an escalating climate emergency. These urgent global issues call for quick action and innovative solutions.

The numbers show us how stark things are. Construction activities and building operations produce more than 40% of the carbon emissions driving global warming.

At the same time, 1.6 billion people live in subpar housing. An alarming 100 million have no house at all. In both Australia and globally, the housing crisis is a pressing and unresolved issue.

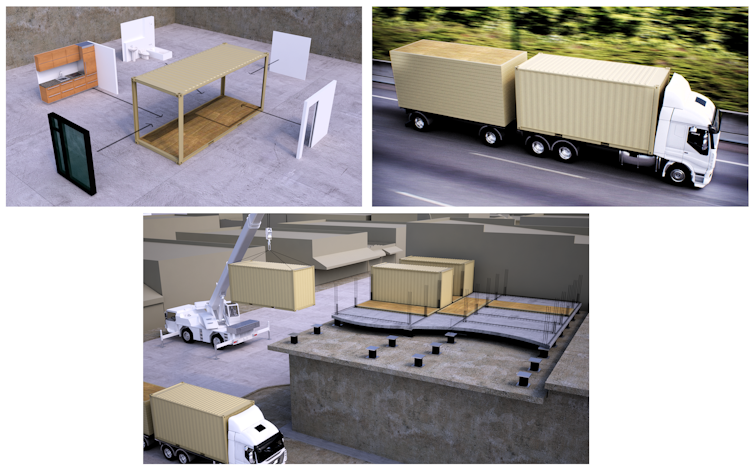

Prefabricated building technology offers promising alternative solutions to this dual crisis. Prefab housing modules are made offsite in a factory. The finished components/modules can then be transported and assembled swiftly at the site of the building.

This approach could transform the housing scene. Affordable dwellings could be produced on a massive scale, while greatly reducing the environmental impacts.

This is not merely about building homes. A shift to prefab construction would be a strategic move in line with the Paris Agreement to mitigate climate change.

Read more: The world needs to build more than two billion new homes over the next 80 years

Cost-efficient and eco-friendly

Prefab modular construction could be considered a greener alternative in the construction sector. By greatly reducing construction waste (which accounts for 40% of landfill) and carbon emissions, it tackles these major environmental concerns head-on. A 2022 study showed modular construction can slash carbon emissions by up to 45% compared to conventional techniques.

The controlled factory-based environment of prefab construction makes it more efficient. This includes integrated reclamation and recycling of construction waste.

This approach is highly cost-effective. It’s about being resource-savvy and reducing waste to the bare minimum.

Read more: Turning the housing crisis around: how a circular economy can give us affordable, sustainable homes

Using standardised designs and components on a large scale also cuts the cost of incorporating energy-efficient elements such as better insulation and renewable energy. Building in this way creates structures that are effective, efficient, resilient and help us combat climate change.

Among many possible construction materials, wood or timber is among the most preferred for prefab modular buildings. Timber is renewable and an efficient carbon sink. The timber in buildings locks away the CO₂ the trees absorbed from the atmosphere when they were growing.

One creative and sustainable solution to housing shortages is to build modular, adjustable prefab dwelling units. These units are robust and can be adapted to various climates and housing needs with ease.

In a world where cities are growing fast and housing needs are pressing, prefab construction can deliver quality, affordable homes at an impressive pace. It’s an efficient solution for a budget-conscious, carbon-constrained world.

Prefab buildings take many forms

The beauty of prefab construction lies in its adaptability, making it the building industry’s chameleon.

It can look good almost anywhere, from bustling cityscapes to serene countryside. Imagine a building technique that can seamlessly transition from a cozy mountain cabin to a stylish metropolitan apartment building.

Read more: Not just daggy dongas: time to embrace prefabricated buildings

Modular homes can be enlarged, modified or even disassembled and moved as communities grow and needs change.

This approach promotes long-term resilience by being adaptable to changes in the climate and housing needs. These buildings are constructed not only for the present, but also for the high-performance requirements of the future.

Read more: Prefab revolution? Factory houses are the secret to green building

Leading examples from overseas

We can learn from success stories overseas.

A community-focused project in England: the prefab modular homes in Cambridge are more than just buildings; they are community cornerstones. As well as providing roofs over heads, the project is about creating a sense of belonging. These units, meticulously designed and sustainably built, are shaping the narrative of affordable housing.

Scandinavian eco-friendly living: Scandinavians have taken modular construction to heart. In this region, known for its design prowess and environmental stewardship, many modular homes are architectural marvels that embody sustainability. Cozy, energy-efficient homes with sleek designs prove that eco-friendly living can be both stylish and functional.

Versatile modular solutions in the Netherlands: Finch Buildings offers a kaleidoscope of sustainable housing. Here, modular construction is about flexibility and diversity, catering to a range of needs and styles. These timber modular solutions can adapt to different lifestyles and preferences. Housing can be as diverse as the people it shelters.

Singapore’s urban blueprint: the city-state is a showcase for the incredible possibilities of prefab modular construction. It’s seamlessly woven into urban planning. Imagine a city where buildings are not just structures, but pieces of a larger, sustainable puzzle. It is a model of how urban development can co-exist with environmental consciousness.

So what’s stopping Australia?

Australia has been slower than many countries to adopt prefab modular construction. The challenges include:

limited government support and incentives compared to other countries

a need for more training and expertise in designing and implementing prefab modular construction

the traditional procurement process in construction is not well suited for prefab methods, so a shift in thinking and approach from construction managers and suppliers is required

the Australian regulatory environment needs to evolve to promote productivity and support modern construction methods like prefabrication

a cultural shift within the industry is also needed, so owners and developers demand more sustainable and efficient construction methods.

The situation is changing in Australia as the housing crisis has intensified. Recognition of the need for more sustainable, efficient construction methods is growing, leading to a gradual shift in government support and industry adoption.

Read more: Building in the same old ways won't end the housing crisis. We need innovation to boost productivity

Making development sustainable

The potential role of prefab modular construction in tackling the challenges of climate change and housing shortages cannot be overstated.

Prefab building is charming not just because it is flexible but also because the architectural features have been thoughtfully considered. Every module can be carefully crafted to complement its surroundings.

Adopting this strategy demonstrates a dedication to development that is ecologically conscious, promotes resilience and sustainability and, by meeting house needs, improves community wellbeing.