To help address climate change, we urgently need to transition to clean energy. The energy sector is a significant contributor to greenhouse gas emissions, which are the primary drivers of global warming.

Our research team at Western University is innovating ways to generate clean electricity. Fuel cells are at the forefront of this endeavour, offering numerous advantages in the pursuit of sustainable energy solutions.

These devices offer a promising pathway to clean energy by efficiently converting chemical energy into electricity with only water and heat as byproducts. This makes them an environmentally friendly choice for electricity generation.

One of the most promising types of fuel cells is the polymer electrolyte membrane fuel cell (PEMFC) because of its applications in transportation, and portable and stationary power sources, where efficiency, responsiveness and reduced emissions are crucial factors.

Platinum as a catalyst

One of the major challenges hindering the widespread adoption of PEMFCs lies with the use of platinum, which is problematic due to its scarcity. This dependency on platinum is due to its ability to facilitate the oxygen reduction reaction (ORR), which is a fundamental process in producing electrical energy within PEMFCs.

The ORR involves the reduction of oxygen molecules into water through a series of complex reactions. This process is responsible for generating the electrical power these fuel cells provide. The presence of platinum as a catalyst lowers the energy required for the reduction of oxygen molecules. Without platinum, the ORR would occur too slowly to yield practical and efficient electricity production.

However, the high cost and scarcity of platinum present substantial challenges to the commercial viability of PEMFCs. The increasing price of platinum has made it economically prohibitive to use it in large-scale fuel cell production, preventing PEMFCs from becoming a mainstream clean energy solution.

Our research works on creating catalysts that can replace platinum effectively. Our research team leverages cutting-edge facilities like the Canadian Light Source, Advanced Photon Source, and the Taiwan Photon Source.

By harnessing these resources and technologies, we explore various strategies for catalyst development, gain profound insights into their structural and chemical characteristics, and better understand how they can advance our goal of reducing dependence on platinum.

Intricate realm of catalyst design

Our research explores catalyst design, with a specific focus on two fundamental techniques: alloying platinum with transition metals and crafting complex core-shell structures.

Alloying platinum is the process of mixing platinum with other transition metals, to enhance catalytic performance. This approach results in catalysts with improved reactivity and durability, rendering them highly effective across a broad spectrum of applications, including fuel cells.

In addition to alloying, our research also delves into the development of intricate core-shell structures. In this approach, a cost-effective metallic core is enveloped by several layers of shell made of another material, providing protection while further enhancing catalytic efficiency.

This design allows for precise control over catalytic reactions, surface property optimization and minimization of material wastage.

Persistent challenges

Despite our advancements, the durability of these catalysts poses a challenge. Their inherent instability, which refers to their tendency to degrade, diminish in effectiveness or undergo undesirable alterations, is a substantial roadblock for real-world applications.

Our research team has found a potential solution: the infusion of cobalt dopants into the surface and near-surface region of catalysts. This creates platinum-based catalysts capable of withstanding harsh conditions and the passage of time. This significantly enhances the durability and effectiveness of these catalysts.

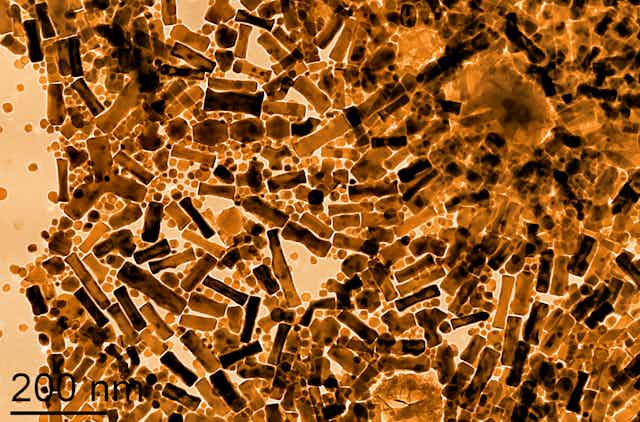

Our team developed novel particles — cobalt-doped palladium-platinum core-shell — which possess a distinctive octahedral structure and exceptional resilience to both harsh chemical environments and prolonged use.

This innovative nanoscale structure, featuring a core of palladium and an outer shell of platinum, with the addition of cobalt atom into the platinum shell, provides these nanoparticles with exceptional durability. They exhibit a remarkable ability to withstand degradation and maintain their catalytic activity over extended periods.

Following a thorough examination involving 20,000 accelerated durability test cycles, designed to provide a better understanding of how catalysts degrade in carefully controlled laboratory conditions, their performance only saw a minimal decrease of two per cent when compared to their initial state at the beginning of the testing.

Potential future

Cobalt-doped palladium-platinum core-shell nanoparticles have the potential to revolutionize fuel cell technology. Their promise as highly efficient and enduring ORR catalysts points the way toward a more sustainable energy future.

Our research aligns with the urgent need to combat climate change as a global crisis. By replacing fossil fuels with cleaner energy alternatives, we can contribute to a more sustainable and resilient future.