Why has the world continued to increase consumption of plastic materials when at the same time, environmental and human health concerns over their use have grown?

One answer is they are immensely useful to humankind, and despite problems they create, they have provided countless benefits. They are used to construct lighter automobiles and planes, improving fuel efficiency and reducing greenhouse gas emissions. Plastic food packaging has dramatically reduced food spoilage, improving human health as well as decreasing emissions associated with transportation and decomposition of waste. In addition to all these upsides, another benefit often quoted is that plastics are recyclable.

At UMass Lowell, where I am based, we argue that “recyclable” must be clearly distinguished from “recycled.” Unfortunately, society has a long way to go before we could declare plastics recycling a success.

My group has been working for the past eight years on sustainability of plastic materials for a range of applications. We study plant-based and biodegradable polymers, improved technologies for recycling plastics and reducing plastics toxicity. Polymers (long-chain organic molecules) are fascinating materials, and they have provided so many benefits to society; however, as population and consumption rates grow, humans must always be mindful of our relationship with the Earth. It is my goal as a researcher, educator and citizen to harness the tools of engineering for environmentally sound plastics production and use.

The plastics recycling infrastructure is flawed

Polymers are large molecules made up of many repeating units. They exhibit diverse mechanical, thermal and chemical properties that make them suitable for a wide range of applications. They are called “plastics” because in theory they can be reshaped multiple times into new products – that is, they are recyclable. In practice, unfortunately, remelting and forming new packaging often degrades the properties of these recycled products, as they are contaminated with impurities from food, labels and other materials.

With the introduction of fines for littering and increasing environmental awareness, the fraction of waste Americans recycle increased steadily starting in the 1970s. In recent decades, however, recycling rates have stalled due to limited technological and logistical options for the materials collected from residential and industrial sites. Today, chemical and polymer companies have become experts at making new plastic products that are durable and inexpensive. Since this new “virgin” plastic is cheap, there is little incentive for using the recycled versions if properties are compromised in any way. Improving recycling performance depends on several complex factors.

The key to recycling plastics: People

The first and most important variable is that people need to participate. In general, Americans show a strong commitment to using recycle bins – when they are made available. But far too many large event centers and point sources of plastics waste do not prioritize collection of recyclable items. Furthermore, the public is confused about which plastic types can and should end up in the recycling bin.

Complex plastic products such as multi-layer film and electronics housings are more difficult to recycle. And current trends suggest that manufacturers are shifting to more complex materials. Bright, multicolored designs end up as a dull brown color when the different packages are melted down. Advanced functionality such as embedded electronics, oxygen barrier layers and other exciting technologies have the unfortunate downside of decreasing the package value in a recycled stream, because separations are difficult and costly.

The technology to sort different varieties of plastic is also lagging. The quality of a recycled plastic depends on its purity. It must be decontaminated from food waste, labels and other polymer types before it is melted down and resold to a product maker. While some automated technologies exist, a large amount of the sorting is still done by hand and the results are imperfect at best.

Once industry demands high quality recycled plastic, then reprocessors will have the confidence to produce a consistent stream to replace some or all of the virgin material they use in their products. The industry needs to standardize the metrics by which the quality of recycle streams are measured.

This wish list for improving the recycling infrastructure may seem insurmountable, but public-private consortia like the REMADE institute are gathering industry stakeholders, university researchers and national labs to tackle the challenge.

An urgent call to action

In July 2017, China announced that it would stop accepting imports of certain classes of waste that come from the recycled streams in other parts of the world. These included contaminated bales of mixed plastics and forms that are challenging to reprocess. This has left piles of waste plastics sitting on loading docks at municipal recycling facilities around the U.S., Canada and Europe.

At the same time, the public outcry over the plastics pollution problem is growing. From the recent efforts to clean up the Great Pacific Garbage Patch to the viral image of a turtle with a straw in its nose that led to widespread rejection of drinking straws, the public is increasingly aware of and demanding solutions to the problem.

Where do we go from here?

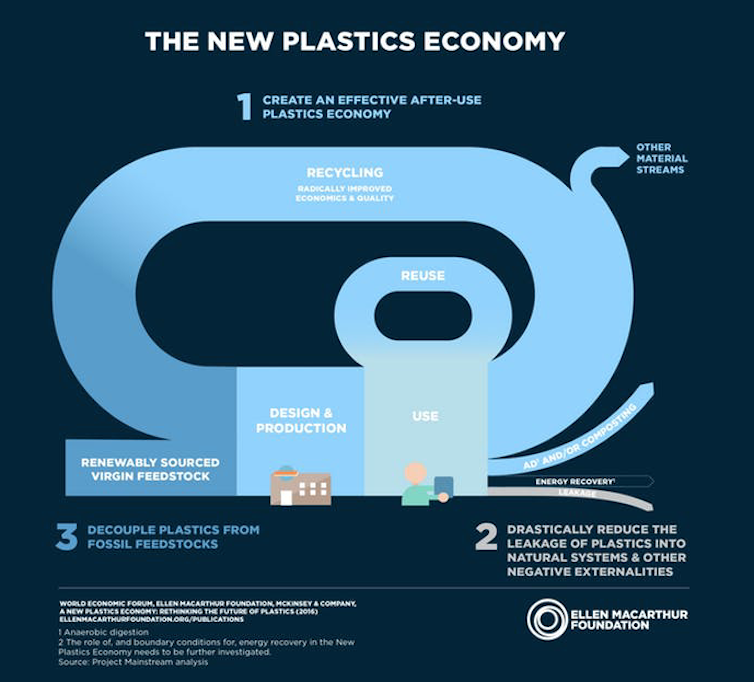

The Ellen MacArthur Foundation is a U.K.-based charitable organization that is focused on transforming the global economy. The foundation has called for a circular economy approach to work toward a new plastics economy. They are working with business, government and academia to shift the way humans consume. Currently society’s throwaway culture supports a linear economy in which items, especially plastics, are used once and tossed out. In a circular economy, plastics would be designed, manufactured and collected in such a way that they could easily be broken down, separated and recycled. As an example, a thoughtfully designed cellphone could be separated into plastics, electronics, glass and other components, and each stream could then be recycled into something just as high quality the second time around – hence the phrase “circular economy.”

The concept introduces a three-pronged approach to eliminate unnecessary plastics we consume, innovate new packaging designs that are more easily recycled or reused, and recirculate more of the plastics we do use through appropriate diversion and reprocessing strategies.

The time is ripe for innovation, but academics, regulatory agencies and stakeholders from multiple points in the value chain must work together. The Plastics Engineering Department here at UMass Lowell is poised to take on the challenge. We are working on new biodegradable polymer recipes and new processes for recycling plastics. We are sharing our findings with the public, collaborating with industry-leading partners and educating next-generation plastics engineers so they can be leaders of change.